Mercury Contamination Could Shut Down Your Project.

We’ll Make Sure It Doesn’t.

Mercury exposure is a serious health risk, and regulatory failure can delay projects and lead to costly fines. Don’t leave your team or your timeline at risk.

- Health Protection – Prevent exposure to hazardous mercury vapor

- Regulatory Compliance – Avoid fines and project shutdowns

- Minimal Downtime – Get back on schedule faster

The Hidden Risks of Mercury Exposure

Why Mercury Cleanup Matters

Mercury spills, often found in cracks, flooring, and old equipment, can release toxic mercury vapors that pose severe health and environmental risks:

- Neurological Damage: Chronic exposure can impair memory, coordination, and motor functions.

- Respiratory Issues: Inhalation of mercury vapors may cause lung and systemic damage.

- Environmental Contamination: Improper disposal of mercury-contaminated waste can pollute ecosystems and water supplies.

Facilities such as laboratories, hospitals, and industrial plants are especially vulnerable to mercury contamination. Proper mercury remediation is crucial to eliminate these risks and ensure ongoing safety.

Why Choose 3D Enviro for Mercury Remediation?

For over 20 years, 3D Enviro has led mercury remediation, combining cutting-edge technology, deep expertise, and federal trust to ensure safe, compliant cleanup. Unlike firms that only assess or remediate, we handle everything—from detection to final clearance—saving you time, money, and stress.

Advanced Detection & Remediation

We use cutting-edge technology, including the Ohio Lumex RA-915+ Mercury Analyzer, to detect and eliminate mercury contamination others might miss—ensuring a thorough, science-backed cleanup.

Safety-First

Approach

We treat every site like our own—protecting your team, visitors, and community with OSHA-compliant protocols and top-tier protective equipment to ensure a truly safe environment.

Trusted Partner

in Crisis

When mercury contamination threatens your project, we respond quickly and decisively—guiding you through every step with expertise, transparency, and a commitment to getting the job done right.

Why Federal Agencies & Contractors Trust 3D Enviro

3D Enviro has completed over $38 million of remediation projects, encompassing some of the most complex and high-risk environments. Our commitment to safety and compliance underscores each project and facility.

Our Work Speaks For Itself

Decades of dedication to safety, efficiency, and client satisfaction.

- 20+ Year Partnership with NIH, managing complex hazardous material projects with zero safety incidents.

- Highwire Gold Safety Award for multiple years, with a safety score consistently between 85-94%.

- 100% Compliance with EPA and OSHA Standards on all projects.

Past Projects

Here are some of the facilities we’ve delivered on:

- Federal & State Research and Test Laboratories

- Hospitals and Clinics

- Power Generation & Transmission Stations

- Public and Private Universities

- Military Installations

- Cooling and Mechanical Plants

Woman-Led, Family-Owned. Built on Trust

Mercury remediation isn’t just our expertise—it’s our legacy. Founded by Dr. Scott Neese, 3D Enviro is now driven by Lauren, Lindsay, and Emily—affectionately known as the “Mercury Sisters”—alongside VP of Operations Nick Kiley.

As a Women-Owned Small Business, we go beyond just meeting federal contracting requirements—we provide specialized mercury solutions that keep your projects safe, compliant, and on track.

When you partner with us, you’re more than just a project. We approach every mercury cleanup with the same precision and care we’d give our own family—because protecting people and the environment is personal to us.

Challenge: Mercury Contamination in a High-Stakes Facility

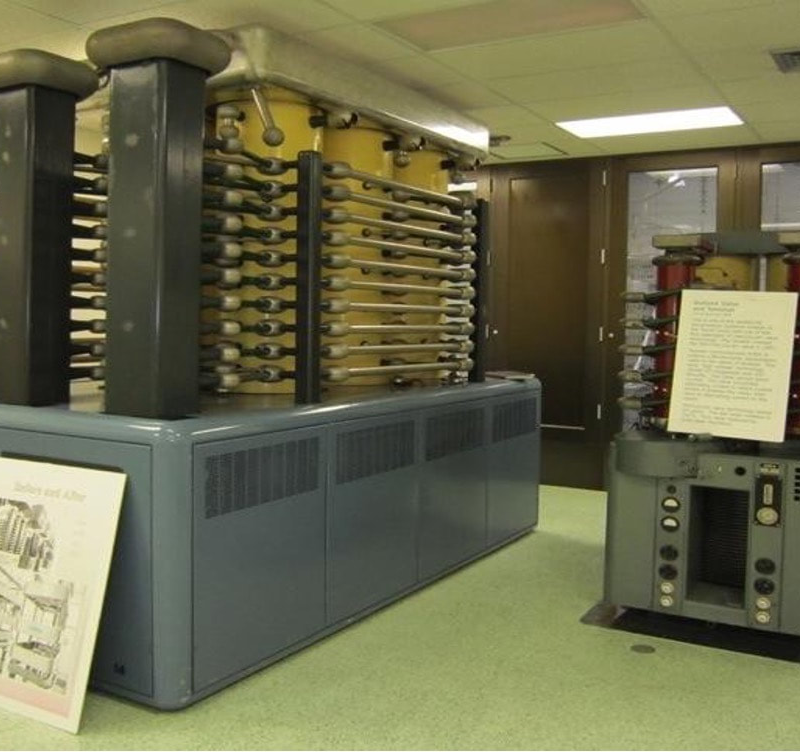

Case Study: Celilo Converter Station at Bonneville Power Administration

The Celilo Converter Station, a key power transmission facility for the Department of Energy (DOE), required comprehensive mercury remediation to address decades of contamination from mercury arc valves. This project posed significant health and operational challenges.

3D Enviro’s Solution

Mercury Spill Cleanup

Collaborated with contractors to recover visible mercury and address contamination in structural elements.

Air Quality Monitoring

Conducted real-time monitoring to ensure compliance throughout the project.

Regulatory Documentation

Provided detailed reports to meet federal compliance standards.

Results

- Reduced mercury levels to safe thresholds.

- Delivered on time and within budget, restoring the station to safe operational status.

Preserving the Environment for Future Generations

Commitment to Environmental Sustainability

We don’t just remove mercury and other hazardous materials— we ensure that remediation leaves a lasting positive impact on the environment and the communities you serve. Our methods are designed to protect ecosystems from toxic materials, safeguarding your future.

Environmental Integrity

Advanced techniques are used prevent the release of hazardous materials into the environment, ensuring long-term safety for our communities.

Sustainable Practices

We continually innovate to reduce the environmental impact of our work and ensure the safety of the ecosystems around project sites.

Future-Proof Solutions

Our thorough remediation practices prevent future liabilities and protect your business from legal and financial risks down the line.

FAQs About Mercury Remediation

How do you remediate mercury?

We use a 4-phase approach that includes historical research, site assessment, decontamination, and clearance testing. This ensures that every spill is identified and remediated safely and efficiently.

What can decontaminate mercury?

Specialized technologies, such as mercury vapor cartridges and advanced air filtration systems, are used to decontaminate spills and neutralize vapors.

How do you get rid of mercury toxins?

Our team uses cutting-edge tools like the Ohio Lumex to monitor toxic mercury vapors to be eliminated by the team, ensuring a safe environment for workers and future occupants.

What are the solutions to mercury contamination?

Proper remediation involves identifying contamination sources, safely removing mercury, and conducting clearance testing to ensure safe environments.

Contact Us for Nationwide Mercury Remediation Services

Don’t let mercury contamination put your facility, staff, or visitors at risk. With 3D Enviro’s expertise in mercury spill cleanup and nationwide capability, you can trust us to deliver safe, compliant solutions for any project.